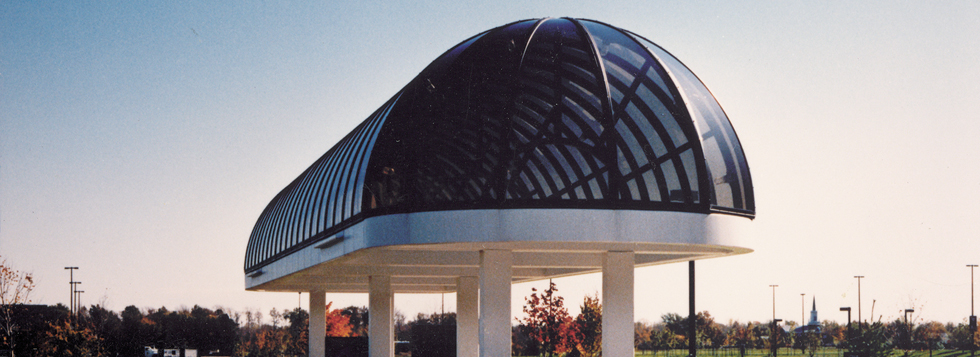

Rotary Draw Bending

This method of curving provides very tight radii compared to both Stretch Forming and Roll Forming. Using this method, the material is clamped to the bend die. As the bend die rotates, another die presses the part into the rotating bend die. This allows for a very high quality part with a very tight radius.

Rotary Draw Bending produces good results at a reasonable cost when the quantities are high. With Rotary Draw Bending, you can have multiple bends in a single piece with minimal distance between the bends.

At Rimac parts can be cut to length, drilled, tapped, notched, punched, and even contoured. This allows us to supply our customers with complete parts ready for assembly.

Let Rimac show you how your most demanding applications are easily achieved.

Please download Rimac's helpful Ordering Guide to help you when ordering. DOWNLOAD

"At Rimac personal service is what we are about"

Back To Services