Roll Forming

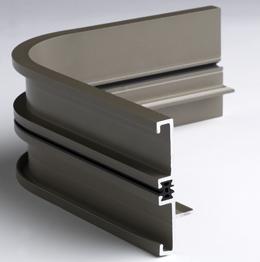

This method of curving provides our customers with the opportunity to curve pre-finished thermally broken sections. Unlike Stretch Forming or Rotary Draw Bending, Roll forming allows for a section to be curved a full 360°.

Roll forming is more economical on prototype and smaller quantities. This method of curving is limited to large radius bends, also it works best with symmetrical sections. Roll forming can provide a faster turnaround time compared to Stretch Forming.

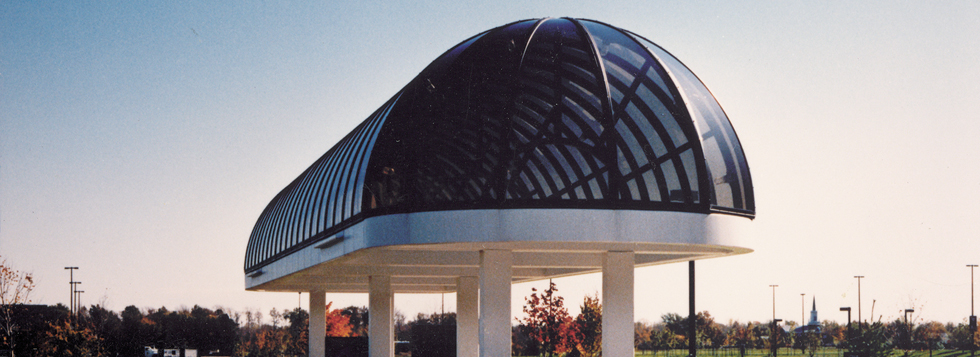

At Rimac parts can be cut to length, drilled, tapped, notched, punched, and even contoured. This allows us to supply our customers with complete parts ready for assembly.

Let Rimac show you how your most demanding applications are easily achieved.

Please download Rimac's helpful Ordering Guide to help you when ordering. DOWNLOAD

"At Rimac personal service is what we are about"

Back To Services