Frequently Asked Questions

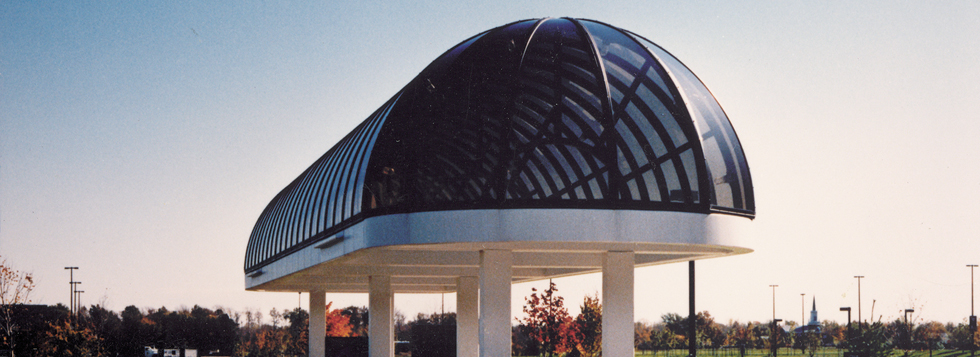

Rimac opened its doors in 1984. Since then, we've curved millions of parts for thousands of customers around the world. We have been able to establish strong and trustworthy relationships with excellent businesses in North America and around the world. Our local customers work with us regularily and our business network is continuing to grow immensely each year. Our hard working team focuses on personal service and continually exceeds customer expectations, while producing quality products on time and on budget.

Often, parts can be manufactured in two weeks or less. Rimac has an assortment of metal bending machines and methods, which allows us to provide some of the best lead times in the industry.

At Rimac, no project is too big or too small. We can handle single, one-off parts, complete multi-storey towers and any sized project in between. To see an array of projects we're proud to have been a part of, see our Gallery.

Reach out to us! Our friendly, knowledgeable staff will help you every step of the way. Most often, quotes can be provided same day. Click Here for our contact information.

Generally, we need to know what material you're planning to use and what shape you require. If you're unsure, Contact Us and we can help you find a solution. Our Ordering Guide is a great place to start.

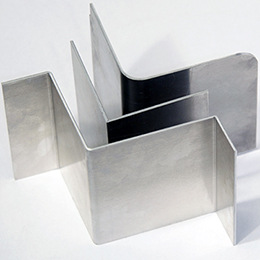

Rimac has a full service Machine shop. Parts can be cut, drilled, tapped, notched, punched, and even contoured. Our Sheet Metal Shear and Press Brake allow us to form custom brake metal shapes up to 4 meters long. This allows us to supply complete parts ready for assembly. We can shear and brake form sheet metal into a shape, curve that shape, and then drill and slot the curved part, all in house.

That depends largely on the shape, size and bend direction of the part being curved. We believe that the best way to answer this question is to have a conversation with us. Our knowledgeable staff will help find a solution that suits your specific needs. Click Here for our contact information.

Rimac has worked with a variety of materials including Aluminum, Steel, Stainless Steel, Brass, Bronze and many other exotic materials. We even curve some plastics such as P.V.C. We specialize in bending extrusion and brake formed material of all shapes and sizes.

Either way is fine. Often, our customers have very specific, custom products of their own; however, we have great relationships with local supliers, who provide competitive pricing and next-day delivery on most items.

Many of our customers use their own preferred carriers. If you need some help with freight, let us know and we can help. We can arrange to pick up the material at your door. If necessary, we'll provide any required documentation to clear it through customs, we'll curve the material, then crate the products for protection and deliver it back to you, providing a true door-to-door service.

"At Rimac personal service is what we are about"

Home